Product Description

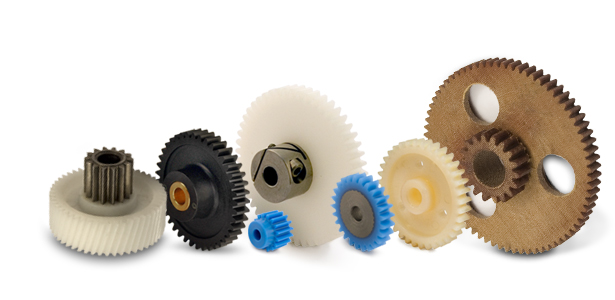

manufacture custom colored engineering plastic uhmwpe chain gear wheel

1.Description:

UHMW-PE(Ultra high Molecular Weight Polyethylene)is a thermoplastic engineering plastic with the average

molecular weight more than 9.2 million (100% Virgin UHMW-PE Raw Material). This kind of material with 5 top performance of high-wear-resistance, good-chemical resistance, low-temperature resistance, self-lubrication and high-impact resistance, which is regarded as a “surprised” engineering plastic of excellent comprehensive capacity and competitive price. HangZhou Engineering Plastics Industries (Group) Company has studied and applied this material in many industries for many years. And we know that it has the following main characteristics:

2.Characteristics:

1. Very high-wear resistance, 7 times wear resistance than steel, 4 times than PTFE

2. Very high anti-impact resistance, 2 times impact resistance than PC, 5 times than ABS.

3. Good self-lubrication, the same as PTFE, better than steel and brass appended lubricating oil.

4. Good anti-corrosion resistance, it has very stable chemicals property and can endure the corrosion of all kinds of corrosive medium and organic solvent in certain rang of temperature and humidity.

5. Very high-inadhesion resistance, the surface of product hardly affixes other material.

6. Very high-impact resistance, 10 times impact resistance than PA66, 8 times than PTFE.

7. Good low temperature resistance, in liquefied nitrogen (- 196ºC), it still has the prolongation.

few other materials can reach to this performance.

8. Non-toxic and clean property, UHMW-PE material that made by HangZhou Engineering Plastics Industries (Group) Company, which meets the Food and Drug Administration (FDA) and United States Department of Agriculture (ASDA) permit to apply in food and medicine fields.

The Main Properties of UHMW-PE

| Property | Item No. | Unit | Value | |

| Mechanical Properties | 1 | Density | g/cm3 | 0.94-0.96 |

| 2 | average molecular weight | g/mol | 9.2X106 | |

| 3 | Tensile strength (23ºC in air) | MPa | 22 | |

| 4 | Breaking strength | MPa | 42 | |

| 5 | Tensile strain at break | % | 600 | |

| 6 | Charpy impact strength (notched) | mJ/mm2 | No break | |

| 7 | Ball indentation hardness | N/mm2 | 42 | |

| 8 | Shore D hardness | — | D65 | |

| 9 | Abrading(sand slurry experiment) | — | 100 | |

| 10 | Coefficient of Friction | — | 0.09~0.1 | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Domestic Appliances |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | POM/Delrin |

| Customization: |

Available

| Customized Request |

|---|

How do you choose the right type of plastic material for specific applications?

Choosing the right type of plastic material for specific applications requires careful consideration of various factors. Here’s a detailed explanation of the process:

1. Identify Application Requirements: Begin by understanding the specific requirements of the application. Consider factors such as temperature range, chemical exposure, mechanical stress, electrical properties, dimensional stability, and regulatory compliance. This initial assessment will help narrow down the suitable plastic material options.

2. Research Plastic Material Properties: Conduct thorough research on different types of plastic materials and their properties. Consider factors such as mechanical strength, thermal stability, chemical resistance, electrical conductivity, impact resistance, UV stability, and food safety approvals. Plastic material datasheets and technical resources from manufacturers can provide valuable information.

3. Evaluate Material Compatibility: Assess the compatibility of the plastic material with the surrounding environment and other components in the system. Consider the potential for chemical reactions, galvanic corrosion, thermal expansion, and any specific requirements for mating surfaces or interfaces. Ensure the selected material is compatible with the intended operating conditions.

4. Consider Manufacturing Process: Evaluate the manufacturing process involved in producing the desired component or product. Different plastic materials may have specific requirements or limitations for processes such as injection molding, extrusion, blow molding, or machining. Ensure the chosen material is compatible with the selected manufacturing method and can meet the desired quality and production efficiency.

5. Assess Cost and Availability: Consider the cost and availability of the plastic material. Some specialty or high-performance plastics may be more expensive or have limited availability compared to more common materials. Evaluate the cost-effectiveness and feasibility of using the selected material within the project’s budget and timeline.

6. Consult with Material Experts: If necessary, consult with material experts, engineers, or suppliers who have expertise in plastic materials. They can provide valuable insights and recommendations based on their experience and knowledge of specific applications. Their input can help ensure the optimal material selection for the intended use.

7. Perform Prototype and Testing: Before finalizing the material selection, it’s advisable to produce prototypes or conduct testing using the chosen plastic material. This allows for verification of the material’s performance, dimensional accuracy, strength, durability, and other critical factors. Iterative testing and evaluation can help refine the material selection process if needed.

By following these steps and considering the application requirements, material properties, compatibility, manufacturing process, cost, and expert advice, it’s possible to choose the most appropriate plastic material for specific applications. Proper material selection is crucial for ensuring optimal performance, longevity, and safety in various industries and products.

Can plastic gears be used in automotive applications?

Yes, plastic gears can be used in automotive applications. Here’s a detailed explanation:

Plastic gears have several advantages that make them suitable for certain automotive applications. They are lightweight, have good wear resistance, offer design flexibility, and can operate with low noise levels. However, it’s important to consider the specific requirements and limitations of automotive applications before using plastic gears.

1. Non-load Bearing Applications: Plastic gears are commonly used in non-load bearing applications within automotive systems. These include applications such as instrument clusters, HVAC systems, seat adjustments, and interior components. In these cases, the gears are subjected to relatively low loads and can effectively perform their functions while offering benefits such as weight reduction and cost efficiency.

2. Auxiliary Systems: Plastic gears can also be used in auxiliary systems of vehicles, such as windshield wipers, window regulators, and sunroof mechanisms. These systems typically operate at lower loads and speeds compared to primary powertrain components. Plastic gears can provide reliable performance in these applications while contributing to weight reduction and improved fuel efficiency.

3. Noise and Vibration: Plastic gears have inherent damping properties that can help reduce noise and vibration in automotive applications. This is particularly advantageous in areas where noise reduction is a priority, such as electric window mechanisms or HVAC systems. Plastic gears can contribute to a quieter and more comfortable driving experience.

4. Design Flexibility: Plastic gears offer design flexibility, allowing for complex shapes and customization to meet specific automotive requirements. They can be molded with precision to achieve intricate gear profiles and optimize gear performance. The flexibility in design can lead to improved efficiency, reduced weight, and space-saving advantages in automotive systems.

5. Material Selection: The selection of the appropriate plastic material is crucial for automotive applications. Certain plastic materials, such as engineering thermoplastics like POM (polyoxymethylene) or PA (polyamide), offer higher strength, rigidity, and wear resistance compared to standard plastics. These materials can withstand the demands of automotive environments, including temperature variations and exposure to chemicals or oils.

6. Load-Bearing Applications: While plastic gears are commonly used in non-load bearing or low-load applications within the automotive industry, they may have limitations in high-load or high-torque applications. Metal gears, such as steel or cast iron, are generally preferred for primary powertrain components such as transmissions and differential systems, where higher strength and durability are required to handle the significant loads and forces involved.

7. Environmental Considerations: Automotive applications can expose gears to various environmental factors such as temperature extremes, humidity, UV radiation, and exposure to chemicals or oils. The selected plastic material should have good resistance to these environmental conditions to ensure long-term durability and performance.

In summary, plastic gears can be successfully used in certain automotive applications, particularly in non-load bearing or low-load scenarios, as well as in auxiliary systems. They offer advantages such as weight reduction, design flexibility, and noise reduction. However, when considering the use of plastic gears in automotive applications, it’s important to carefully evaluate the specific requirements, loads, environmental conditions, and material selection to ensure optimal performance and durability.

What industries commonly use plastic gears?

Plastic gears find applications in various industries due to their unique properties and advantages. Here’s a detailed explanation of the industries that commonly use plastic gears:

- Automotive: Plastic gears are used in automotive applications such as power windows, seat adjusters, HVAC systems, windshield wipers, and various motor-driven mechanisms. Their lightweight nature, noise reduction capabilities, and corrosion resistance make them suitable for these applications.

- Consumer Electronics: Plastic gears are used in consumer electronics devices like printers, scanners, cameras, and audio equipment. Their lightweight construction, low noise generation, and design flexibility make them ideal for compact and noise-sensitive applications.

- Medical: Plastic gears are utilized in medical devices and equipment such as pumps, lab instruments, diagnostic devices, and surgical equipment. Their corrosion resistance, lubricity, and ability to be sterilized make them suitable for medical environments.

- Office Equipment: Plastic gears are commonly found in office equipment like printers, photocopiers, scanners, and shredders. Their low noise operation, lightweight construction, and cost-effectiveness make them popular choices in these applications.

- Industrial Machinery: Plastic gears are used in various industrial machinery applications, including packaging equipment, conveyor systems, material handling equipment, and small gearboxes. Their self-lubricating properties, corrosion resistance, and noise reduction capabilities make them suitable for these industrial environments.

- Toys and Games: Plastic gears are extensively used in toys, hobbyist models, and games. Their lightweight nature, cost-effectiveness, and ease of customization allow for the creation of intricate moving parts in these recreational products.

- Aerospace: Plastic gears are used in certain aerospace applications, particularly in non-critical systems such as cabin equipment, small actuators, and control mechanisms. Their lightweight construction and noise reduction characteristics are advantageous in aerospace applications.

- Telecommunications: Plastic gears find applications in telecommunications equipment such as routers, switches, and communication devices. Their lightweight design, noise reduction properties, and cost-effectiveness make them suitable for these applications.

These are just a few examples of the industries that commonly use plastic gears. The versatility, cost-effectiveness, design flexibility, and specific performance characteristics of plastic gears make them valuable components in numerous applications across various sectors.

editor by CX 2024-04-08

China manufacturer Precision Customized Nylon POM Mini Plastic Spur Gear Worm Gears with Best Sales

Product Description

Precision Customized Nylon POM Mini Plastic Spur Gear Worm Gears

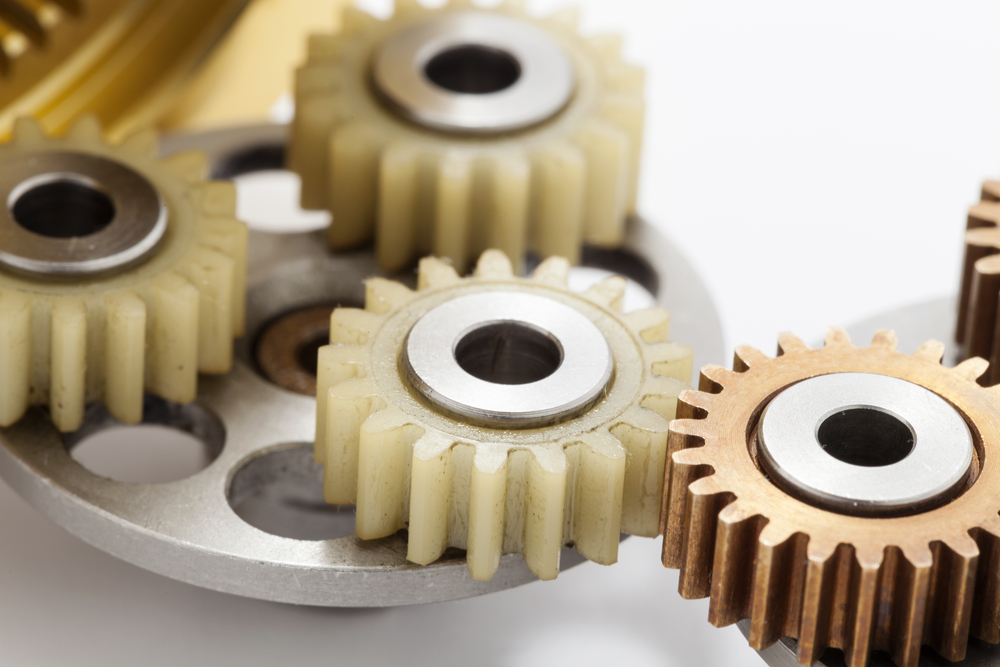

Gear transmission relies on the thrust between gear teeth to transmit motion and power, also known as meshing transmission. With this gradual meshing, helical gears operate much more smoothly and quietly than spur gears. Therefore, almost all automobile transmissions use helical gears.Since the teeth on the helical gear present a certain angle, the gears will be under a certain amount of stress when they mesh. Equipment using helical gears is equipped with bearings to withstand this pressure.

Product Description

| Product name | Worm Gear and Worm Wheel & Plastic Gear & Nylon Gear |

| Materials Available | Stainless Steel, Carbon Steel, Brass, Bronze, Iron, Aluminum Alloy,Copper,Plastic etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Surface Treatment | Carburizing and Quenching,Tempering ,Tooth suface high quenching Hardening,Tempering |

| BORE | Finished bore, Pilot Bore, Special request |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Pressure Angle | 20 Degree |

| Hardness | 55- 60HRC |

| Size | Customer Drawings & ISO standard |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001:2008 |

| Applications | Electric machinery, metallurgical machinery, environmental protection machinery, electronic and electrical appliances, road construction machinery, chemical machinery, food machinery, light industrial machinery, mining machinery, transportation machinery, construction machinery, building materials machinery, cement machinery, rubber machinery, water conservancy machinery and petroleum machinery |

| Machining Process | Material preparation, normalizing, rough turning, quenching and tempering, semi fine turning outer circle, rough turning spiral surface, fine turning (fine grinding) inner hole end face, keyway, semi fine turning spiral surface, pliers (rest incomplete teeth), semi fine grinding outer circle, semi fine grinding spiral surface, grinding center hole, fine grinding outer circle, fine grinding spiral surface, finished product inspection |

| Advantages | 1. Produce strictly in accordance with ANSI or DIN standard dimension 2. Material: SCM 415 steel 3. Bore: Finished bore 4. Precision grade: DIN 5 to DIN 7 5. Surface treatment: Carburizing and Quenching 6. Module: From 1 to 4 7. Tooth: From Z15 to Z70 |

Company Profile

FAQ

| Main Markets? | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order? | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

If you are interested in our products, please tell us which materials, type, width, length u want.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Automation Equipment |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you provide examples of machinery that use worm gears?

Worm gears are utilized in various machinery and mechanical systems where precise motion control, high gear reduction ratios, and self-locking capabilities are required. Here are some examples of machinery that commonly use worm gears:

- Elevators: Worm gears are commonly employed in elevator systems to control the vertical movement of the elevator car. The high gear reduction ratio provided by worm gears allows for smooth and controlled lifting and lowering of heavy loads.

- Conveyor systems: Worm gears are used in conveyor systems to drive the movement of belts or chains. The self-locking nature of worm gears helps prevent the conveyor from back-driving when the power is turned off, ensuring that the materials or products being transported stay in place.

- Automotive applications: Worm gears can be found in automotive steering systems. They are often used in the steering gearboxes to convert the rotational motion of the steering wheel into lateral movement of the vehicle’s wheels. Worm gears provide mechanical advantage and precise control for steering operations.

- Milling machines: Worm gears are utilized in milling machines to control the movement of the worktable or the spindle. They offer high torque transmission and accurate positioning, facilitating precise cutting and shaping of materials during milling operations.

- Lifts and hoists: Worm gears are commonly employed in lifting and hoisting equipment, such as cranes and winches. Their high gear reduction ratio allows for the lifting of heavy loads with minimal effort, while the self-locking property prevents the load from descending unintentionally.

- Rotary actuators: Worm gears are used in rotary actuators to convert linear motion into rotary motion. They are employed in various applications, including valve actuators, robotic arms, and indexing mechanisms, where controlled and precise rotational movement is required.

- Packaging machinery: Worm gears find application in packaging machinery, such as filling machines and capping machines. They assist in controlling the movement of conveyor belts, rotating discs, or cam mechanisms, enabling accurate and synchronized packaging operations.

- Printing presses: Worm gears are utilized in printing presses to control the paper feed and the movement of the printing plates. They provide precise and consistent motion, ensuring accurate registration and alignment of the printed images.

These are just a few examples, and worm gears can be found in many other applications, including machine tools, textile machinery, food processing equipment, and more. The unique characteristics of worm gears make them suitable for various industries where motion control, high torque transmission, and self-locking capabilities are essential.

Can worm gears be used in automotive applications?

Yes, worm gears can be used in certain automotive applications. Here’s a detailed explanation of their use in the automotive industry:

1. Steering Systems: Worm gears are commonly used in automotive steering systems, particularly in older vehicles. They can provide the necessary torque and precision for steering control. The self-locking feature of worm gears is advantageous in steering applications as it helps maintain the desired steering position even when external forces are applied. However, it’s important to note that many modern vehicles have transitioned to other steering mechanisms such as rack and pinion for improved efficiency and performance.

2. Window Regulators: Worm gears can be found in power window regulator systems in some vehicles. They help convert rotational motion into linear motion, allowing for the smooth and controlled movement of windows. Worm gears in window regulators are often paired with a mechanical linkage system to distribute the motion to multiple windows.

3. Convertible Top Mechanisms: In convertible vehicles, worm gears can be utilized in the mechanisms that raise and lower the convertible top. The high torque capabilities of worm gears make them suitable for these applications, as they can effectively handle the load of the top and ensure smooth and reliable operation.

4. Accessory Drives: Worm gears can be employed in accessory drives within the automotive engine compartment. They can be used to transfer power from the engine to various accessories such as water pumps, fuel pumps, and air compressors. However, it’s important to note that other power transmission mechanisms such as belts and pulleys or gear drives are more commonly used in modern automotive accessory drive systems due to their higher efficiency and compact design.

5. Limited-Slip Differentials: Worm gears can be incorporated into limited-slip differentials in some automotive applications. Limited-slip differentials distribute torque between the wheels to improve traction and stability. Worm gears can provide the necessary torque multiplication and torque biasing capabilities required for limited-slip differentials.

While worm gears can be found in these automotive applications, it’s important to consider that other power transmission mechanisms such as spur gears, bevel gears, and belt drives are more commonly used in modern automotive designs. These alternatives often offer higher efficiency, compactness, and better performance characteristics for automotive applications. Additionally, advancements in technology and the pursuit of lightweight and efficient designs have led to the adoption of alternative power transmission systems in many automotive applications.

Overall, while worm gears have a place in certain automotive applications, their use is more limited compared to other power transmission mechanisms commonly employed in the automotive industry.

How do you choose the right size worm gear for your application?

Choosing the right size worm gear for your application involves considering several factors to ensure optimal performance and longevity. Here are the key considerations:

Load Requirements:

Determine the maximum load that the worm gear will need to transmit. This includes both the torque (rotational force) and the axial load (force along the axis of the gear). Calculate or estimate the peak and continuous loads that the gear will experience during operation. Consider factors such as shock loads, dynamic forces, and variations in load conditions. This information will help determine the required load-carrying capacity of the worm gear.

Gear Ratio:

Determine the desired gear ratio for your application. The gear ratio determines the speed reduction and torque multiplication provided by the worm gear system. Consider the specific requirements of your application, such as the desired output speed and the torque needed to drive the load. Select a worm gear with a gear ratio that meets your application’s requirements while considering the limitations of the available gear options.

Efficiency:

Consider the efficiency requirements of your application. Worm gears typically have lower efficiency compared to other types of gears due to the sliding action between the worm and worm wheel. If efficiency is critical for your application, choose a worm gear design and materials that offer higher efficiency, such as a double enveloping worm gear.

Space Constraints:

Evaluate the available space for the worm gear assembly in your application. Consider the dimensions of the worm gear, including the diameter, length, and mounting requirements. Ensure that the chosen worm gear can fit within the available space without compromising other components or functionality.

Speed and Operating Conditions:

Consider the operating speed and environmental conditions in which the worm gear will operate. Some worm gears have speed limitations due to factors such as heat generation and lubrication requirements. Ensure that the selected worm gear is suitable for the anticipated speed range and can withstand the temperature, humidity, and other environmental factors of your application.

Manufacturing Standards and Quality:

Select a worm gear that conforms to recognized manufacturing standards and quality requirements. Look for worm gears from reputable manufacturers that offer reliable and durable products. Consider factors such as material quality, surface finish, and precision in the gear manufacturing process.

By carefully evaluating these factors and considering the specific requirements of your application, you can choose the right size worm gear that meets your performance, load, and space requirements, resulting in a reliable and efficient gear system.

editor by CX 2024-04-08

China manufacturer Industrial Transmission POM Nylon UHMWPE Spur CZPT Gear Plastic Gears raw gear

Product Description

Product Description

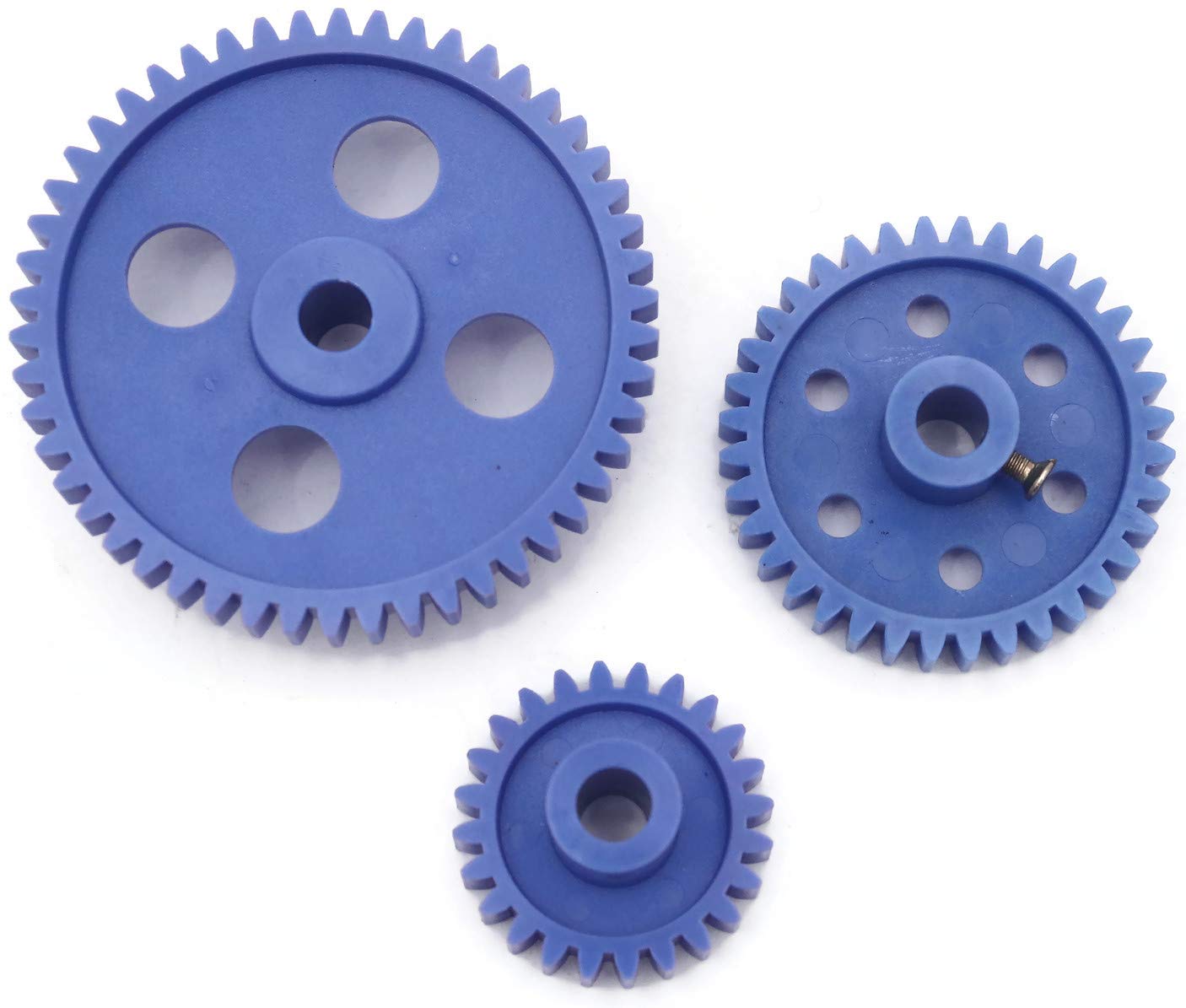

Gears, are widely used in conveyor system. According to the shape, there are spur gear, bevel gear, helical gear, pin gear, double gear and etc. According the using situation, gears involved in driving gears and drived gears. According to different using environment, there are different materials to choice, such as: HCPP, PVDF, PVC, POM, PA, PFA, PEEK, ETFE and etc. Main parameter for gears, there are: ID, OD, Teeth quantity, M, Length, Center circle. As we know: M*Teeth quantity=Center circle, so if you have any requirements, pls contact with us. We have professional design team, we can design drawing and choose suitable material for you, as your requirements.

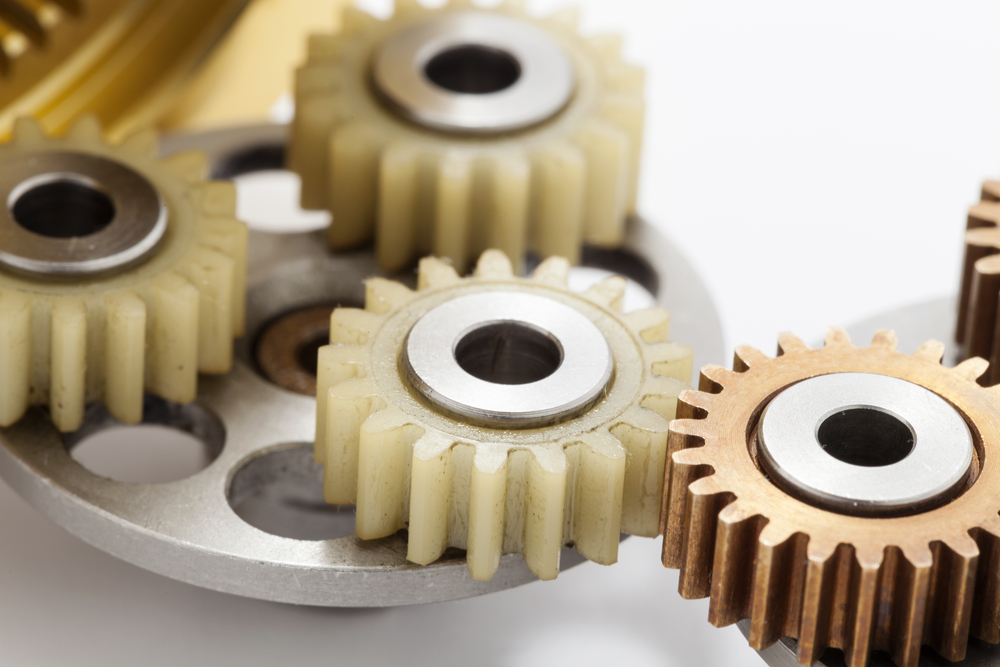

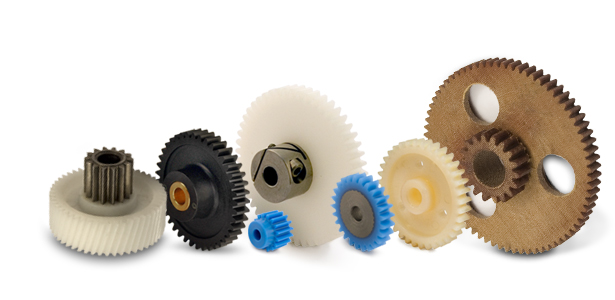

Detailed Photos

Features

1- wear-resistant

2- corrosion resistance

3- transfer smooth

4- low transmission sound

5- easy to install and repair replacement

Product Parameters

| Name | Material | ID | Center Circle |

| Spur Gear | HCPP, PVDF, PVC, POM, PA, PFA, PEEK, ETFE and etc. | ID8, ID10, ID12, ID12.7, ID15, ID16 and etc. | 16, 18, 20, 22, 24, 25, 30, 32, 35, 40, 48, 50 and etc. |

| Bevel Gear | |||

| Helical Gear | |||

| Pin Gear | |||

| Double Gear |

Note: If you need order gears, pls provide the data as the drawing:

Other Products

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How to order ?

A: Normally you can order our products by using Made-in China platform or contacting representatives by Email.

After we receive your messages, we will help you to choose the right specifications and other inquiries.

Then we will send an proforma invoice to you via mail, it includes details of your order and our bank information.

After we received your payment by TT, we will ship your goods and we will send the invoice, packing list, and the express tracking number via mail.

Q: What is our term of trade ?

A: Usually we use EX WORKS. If you need other term of trade, please let us know.

Q: How to pay ?

A: We accept the payment by T/T (bank transfer) or pay through Made-in China platform.

Please inquire us about the details in advance.

Q: How are you going to deliver our goods ?

A: We can ship your goods either by air express (FedEx, DHL, UPS, TNT etc) or by sea.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | PCB Machine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Injection Molding |

| Toothed Portion Shape: | Spur Gear |

| Material: | Plastic |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do plastic gears contribute to reducing noise and vibration?

Plastic gears contribute to reducing noise and vibration in various applications. Here’s a detailed explanation of how they achieve this:

Plastic gears possess inherent properties that help dampen noise and vibration during operation. These properties, combined with specific design considerations, contribute to the reduction of noise and vibration in the following ways:

- Damping Characteristics: Plastic materials have inherent damping characteristics, meaning they have the ability to absorb and dissipate vibrations. When compared to metal gears, which are stiffer and transmit vibrations more efficiently, plastic gears can effectively reduce the transmission of vibrations through their damping properties.

- Reduced Resonance: Plastic gears have the ability to attenuate resonant frequencies, which are frequencies at which vibrations can be amplified. By properly designing the tooth profile, gear geometry, and material selection, plastic gears can shift or dampen these resonant frequencies, preventing excessive vibration and noise generation.

- Tighter Gear Mesh Tolerances: Plastic gears can be manufactured with tighter gear mesh tolerances, which refers to the amount of clearance or backlash between mating gear teeth. Tighter tolerances lead to better gear engagement and reduced impact or vibration during gear meshing, resulting in quieter operation.

- Surface Finishes: The surface finish of plastic gears can be optimized to reduce friction and noise. Smoother gear surfaces reduce the potential for gear tooth noise and improve the overall meshing characteristics between gears. Proper lubrication or the use of self-lubricating plastic materials can further enhance the noise-reducing properties.

- Flexibility in Tooth Design: Plastic gears offer greater flexibility in tooth design compared to metal gears. Engineers can optimize the tooth profile and modify the gear geometry to minimize noise and vibration. For example, incorporating modifications such as profile shifting, tip relief, or helical teeth can help reduce gear noise by promoting smoother and more gradual tooth engagements.

By leveraging these characteristics and design considerations, plastic gears can effectively reduce noise and vibration levels in various applications. This makes them particularly suitable for use in noise-sensitive environments, such as consumer electronics, automotive components, or office equipment.

It’s important to note that while plastic gears can contribute to noise and vibration reduction, the specific noise performance also depends on other factors within the overall system, such as gear arrangement, supporting structures, and the presence of other noise sources. Therefore, a holistic approach to noise reduction should be considered when incorporating plastic gears into a design.

How do you prevent premature wear and degradation in plastic gears?

Preventing premature wear and degradation in plastic gears requires implementing various measures and considerations. Here’s a detailed explanation of how to achieve this:

1. Material Selection: Choose a plastic material with suitable properties for the specific application. Consider factors such as strength, stiffness, wear resistance, and compatibility with operating conditions. Opt for materials that have good resistance to wear, fatigue, and environmental factors to minimize premature degradation.

2. Gear Design: Pay attention to the design of the plastic gears to minimize wear and degradation. Optimize the tooth profile, gear geometry, and load distribution to reduce stress concentrations and ensure even load sharing among the teeth. Incorporate features such as fillets, reinforcements, and optimized tooth profiles to enhance the gear’s durability.

3. Lubrication: Proper lubrication is essential to reduce friction, minimize wear, and prevent premature degradation. Choose lubricants that are compatible with the plastic material and the operating conditions. Ensure adequate lubrication by following manufacturer recommendations and implementing proper lubrication techniques such as oil bath, grease, or dry lubrication.

4. Operating Conditions: Consider the operating conditions and make adjustments to prevent premature wear and degradation. Control operating temperatures within the recommended range for the plastic material to avoid thermal degradation. Avoid excessive speeds or loads that can lead to increased friction and wear. Minimize exposure to harsh chemicals, UV radiation, or abrasive particles that can degrade the plastic material.

5. Maintenance: Implement regular maintenance practices to prevent premature wear and degradation. Conduct periodic inspections to identify signs of wear or damage. Replace worn or damaged gears promptly to prevent further degradation. Follow recommended maintenance schedules for lubrication, cleaning, and any other specific requirements for the plastic gears.

6. Proper Installation: Ensure that plastic gears are installed correctly to minimize wear and degradation. Follow manufacturer guidelines and recommendations for installation procedures, such as proper alignment, torque values, and fastening techniques. Improper installation can lead to misalignment, increased stress concentrations, and accelerated wear.

7. Optimized Load Distribution: Design the gear system to ensure even load distribution across the gear teeth. Consider factors such as tooth profile, tooth width, and the number of teeth to optimize load sharing. Uneven load distribution can lead to localized wear and premature degradation of specific gear teeth.

8. Environmental Protection: Protect plastic gears from harsh environmental conditions that can accelerate wear and degradation. Implement measures such as sealing mechanisms, coatings, or encapsulation to shield the gears from exposure to chemicals, moisture, UV radiation, or abrasive particles.

9. Quality Manufacturing: Ensure high-quality manufacturing processes to minimize defects and inconsistencies that can compromise the durability of plastic gears. Use reputable suppliers and manufacturers that adhere to strict quality control measures. Conduct thorough inspections and testing to verify the quality of the gears before installation.

By considering these preventive measures, such as material selection, gear design, lubrication, operating conditions, maintenance, proper installation, load distribution optimization, environmental protection, and quality manufacturing, it’s possible to minimize premature wear and degradation in plastic gears, ensuring their longevity and performance.

What are the advantages of using plastic gears in machinery?

Plastic gears offer several advantages when used in machinery. Here’s a detailed explanation of the advantages of using plastic gears:

- Lightweight: Plastic gears are significantly lighter in weight compared to metal gears. This lightweight characteristic is particularly beneficial in applications where weight reduction is important, as it can contribute to energy efficiency, lower inertia, and reduced wear on supporting components.

- Low Noise and Vibration: Plastic gears have inherent damping properties, which help reduce noise and vibration levels during operation. The ability to absorb and dissipate vibrations leads to quieter machinery, making plastic gears suitable for applications where noise reduction is desired, such as in consumer electronics or office equipment.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals. This makes plastic gears suitable for applications in corrosive environments, where metal gears may suffer from degradation or require additional protective coatings.

- Self-Lubrication: Some plastic materials used for gear manufacturing have self-lubricating properties. These materials can reduce friction and wear between gear teeth, eliminating the need for external lubrication. Self-lubricating plastic gears can simplify maintenance requirements and reduce the risk of lubricant contamination or leakage in machinery.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production. Plastic materials are often less expensive than metals, and the manufacturing processes for plastic gears can be more efficient, resulting in lower overall production costs. This cost advantage makes plastic gears an attractive option for applications where budget considerations are important.

- Design Flexibility: Plastic gears offer greater design flexibility compared to metal gears. Plastic materials can be easily molded into complex shapes, allowing for the creation of custom gear profiles and tooth geometries. This design flexibility enables gear optimization for specific applications, improving performance, efficiency, and overall machinery design.

- Electrical Insulation: Plastic gears provide electrical insulation properties, which can be advantageous in machinery where electrical or electronic components are in close proximity to the gears. The electrical insulation helps prevent the risk of electrical short circuits or interference caused by metal gears coming into contact with conductive parts.

It’s important to note that while plastic gears offer unique advantages, they also have limitations. They may not be suitable for applications requiring extremely high torque, high temperatures, or where precise positioning is critical. The selection of plastic gears should consider the specific requirements of the machinery and the mechanical properties of the chosen plastic material.

editor by CX 2024-04-04

China OEM OEM Custom CNC Machining Nylon Helical Bevel Worm Oval Wheel Bevel Making Small Spur Plastic Gear bevel spiral gear

Product Description

Product Description

|

CNC Machining Finishes |

Plastic Materials |

Metal CNC Machining Materials |

|

Standard (As-Milled) |

ABS |

CNC Machining Aluminum Alloys |

|

Bead Blast |

Acrylic |

CNC Machining Copper Alloys |

|

Tumbled |

Delrin (Acetal) |

CNC Machining Bronze Alloys |

|

Anodized (Type II Or Type III) |

Garolite |

CNC Machining Brass Alloys |

|

Titanium Anodize |

HDPE |

CNC Machining Stainless Steel Alloys |

|

PTFE Impregnated Hard Anodize |

Nylon 6/6 |

CNC Machining Steel Alloys |

|

Chem Film (Chromate Conversion Coating) |

PC (Polycarbonate) |

CNC Machining Titanium Alloys |

|

Passivation |

PEEK |

CNC Machining Zinc Alloys |

|

Powder Coat |

Polypropylene |

|

|

Electropolishing |

PTFE |

|

|

Electroless Nickel Plating |

UHMW PE |

|

|

Silver Plating |

PVC |

|

|

Gold Plating |

ULTEM |

|

|

Zinc Plating |

|

Detailed Photos

Company Profile

HangZhou Hangjia Metal Technology Limited

We are a supplier specializing in hardware customized machining metal parts manufacturing services established in June 2014 with a factory covering an area of 2,100 square feet. The company has strong technical force, perfect quality system, with CNC computerized lathe, automatic lathe, drilling machine, CNC turning and milling composite machine, precision engraving machine and other types of machining equipment and advanced testing equipment, which engineering technology and management personnel, and passed the certification of ISO9001-2015 quality system in 2017.

In line with the principle of honesty and trustworthiness, our company strictly controls the quality of products and processes, so as to free you from worries. In addition, we also provide sheet metal processing, stamping, bending, laser cutting and injection molding. We can provide one-stop service to complete your whole project. We absolutely provide our customers with the highest quality and on-time delivery.

Our Advantages

Hangjia Quality Promise

★ 15 days is on approval 365 days is replaceable

★ ISO 9001 certified, AS 9100 &ISO 13485 compliant

★ Material certifications available

★ Inspection reports included with every order

★ Quality guaranteed. lf a part is not made to spec, we’ll make it right.

|

|

Metal, PEEK AND ULTEM |

Other Plastic |

|

Linear Dimension |

+/-0.01mm +/-0.0003incn |

+/-0.05mm +/-0.002incn |

|

Hole Diameters(Not Reamed) |

+/-0.008mm +/-0.0003incn |

+/-0.05mm +/-0.002incn |

|

Shaft Diameters |

+/-0.004mm +/-0.00016incn |

+/-0.05mm +/-0.002incn |

Inspections:

3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues,Thread and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness testers, etc. ( Detection accuracy to 0.001 millimetre )

FAQ

Q1: Where can I get product & price information?

A1: Send us an inquiry e-mail, we will contact you once we received your mail.

Q2: How long will I get the sample?

A2: Depends on your specific items, within 3-7 days generally.

Q3: What kinds of information do you need for a quote?

A3: Kindly please provide the product drawings in PDF, if provide in STEP or IGS will be better.

Q4: What are the payment terms?

A4: We accept 50% as a payment deposit, when the goods are prepared, we shoot photos or videos for your check, and then you can

pay the balance. For small quantities, we accept Paypal, the commission will be added to the order. For big amounts, T/T is

preferred.

Q5: How to deliver the goods?A5: We deliver the products by courier company.

Q6: Are you a trading company or factory?

A6: We are factory direct with 17 experienced engineers and more than 50 employees as well approximate 5,000m2 workshop area.

Q7: What shall we do if we don’t have drawings?

A7: Please send your sample to our factory, then we can copy and provide you better solutions. If send us pictures or drafts with

dimensions(Length, Height, Width), CAD or 3D file will be made for you.

Q8: Can we get some samples before mass production?

A8: Absolutely yes.

Q9: Will my drawings be safe after sending them to you?

A9: Yes, we will keep them well and won’t release them to the third party without your permission.

Q10: Is it possible to know the operation status of my products without visiting your company?

A10: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the

machining progress.

Q11: If you make poor quality goods, will you refund?

A11: In fact, we won’t take risks to produce poor-quality products. Meanwhile, we manufacture good quality products till you are

satisfied.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Spare Parts |

|---|---|

| Warranty: | 1 Year, Free Spare Parts |

| Condition: | New |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do plastic gears contribute to reducing noise and vibration?

Plastic gears contribute to reducing noise and vibration in various applications. Here’s a detailed explanation of how they achieve this:

Plastic gears possess inherent properties that help dampen noise and vibration during operation. These properties, combined with specific design considerations, contribute to the reduction of noise and vibration in the following ways:

- Damping Characteristics: Plastic materials have inherent damping characteristics, meaning they have the ability to absorb and dissipate vibrations. When compared to metal gears, which are stiffer and transmit vibrations more efficiently, plastic gears can effectively reduce the transmission of vibrations through their damping properties.

- Reduced Resonance: Plastic gears have the ability to attenuate resonant frequencies, which are frequencies at which vibrations can be amplified. By properly designing the tooth profile, gear geometry, and material selection, plastic gears can shift or dampen these resonant frequencies, preventing excessive vibration and noise generation.

- Tighter Gear Mesh Tolerances: Plastic gears can be manufactured with tighter gear mesh tolerances, which refers to the amount of clearance or backlash between mating gear teeth. Tighter tolerances lead to better gear engagement and reduced impact or vibration during gear meshing, resulting in quieter operation.

- Surface Finishes: The surface finish of plastic gears can be optimized to reduce friction and noise. Smoother gear surfaces reduce the potential for gear tooth noise and improve the overall meshing characteristics between gears. Proper lubrication or the use of self-lubricating plastic materials can further enhance the noise-reducing properties.

- Flexibility in Tooth Design: Plastic gears offer greater flexibility in tooth design compared to metal gears. Engineers can optimize the tooth profile and modify the gear geometry to minimize noise and vibration. For example, incorporating modifications such as profile shifting, tip relief, or helical teeth can help reduce gear noise by promoting smoother and more gradual tooth engagements.

By leveraging these characteristics and design considerations, plastic gears can effectively reduce noise and vibration levels in various applications. This makes them particularly suitable for use in noise-sensitive environments, such as consumer electronics, automotive components, or office equipment.

It’s important to note that while plastic gears can contribute to noise and vibration reduction, the specific noise performance also depends on other factors within the overall system, such as gear arrangement, supporting structures, and the presence of other noise sources. Therefore, a holistic approach to noise reduction should be considered when incorporating plastic gears into a design.

Can plastic gears be used in automotive applications?

Yes, plastic gears can be used in automotive applications. Here’s a detailed explanation:

Plastic gears have several advantages that make them suitable for certain automotive applications. They are lightweight, have good wear resistance, offer design flexibility, and can operate with low noise levels. However, it’s important to consider the specific requirements and limitations of automotive applications before using plastic gears.

1. Non-load Bearing Applications: Plastic gears are commonly used in non-load bearing applications within automotive systems. These include applications such as instrument clusters, HVAC systems, seat adjustments, and interior components. In these cases, the gears are subjected to relatively low loads and can effectively perform their functions while offering benefits such as weight reduction and cost efficiency.

2. Auxiliary Systems: Plastic gears can also be used in auxiliary systems of vehicles, such as windshield wipers, window regulators, and sunroof mechanisms. These systems typically operate at lower loads and speeds compared to primary powertrain components. Plastic gears can provide reliable performance in these applications while contributing to weight reduction and improved fuel efficiency.

3. Noise and Vibration: Plastic gears have inherent damping properties that can help reduce noise and vibration in automotive applications. This is particularly advantageous in areas where noise reduction is a priority, such as electric window mechanisms or HVAC systems. Plastic gears can contribute to a quieter and more comfortable driving experience.

4. Design Flexibility: Plastic gears offer design flexibility, allowing for complex shapes and customization to meet specific automotive requirements. They can be molded with precision to achieve intricate gear profiles and optimize gear performance. The flexibility in design can lead to improved efficiency, reduced weight, and space-saving advantages in automotive systems.

5. Material Selection: The selection of the appropriate plastic material is crucial for automotive applications. Certain plastic materials, such as engineering thermoplastics like POM (polyoxymethylene) or PA (polyamide), offer higher strength, rigidity, and wear resistance compared to standard plastics. These materials can withstand the demands of automotive environments, including temperature variations and exposure to chemicals or oils.

6. Load-Bearing Applications: While plastic gears are commonly used in non-load bearing or low-load applications within the automotive industry, they may have limitations in high-load or high-torque applications. Metal gears, such as steel or cast iron, are generally preferred for primary powertrain components such as transmissions and differential systems, where higher strength and durability are required to handle the significant loads and forces involved.

7. Environmental Considerations: Automotive applications can expose gears to various environmental factors such as temperature extremes, humidity, UV radiation, and exposure to chemicals or oils. The selected plastic material should have good resistance to these environmental conditions to ensure long-term durability and performance.

In summary, plastic gears can be successfully used in certain automotive applications, particularly in non-load bearing or low-load scenarios, as well as in auxiliary systems. They offer advantages such as weight reduction, design flexibility, and noise reduction. However, when considering the use of plastic gears in automotive applications, it’s important to carefully evaluate the specific requirements, loads, environmental conditions, and material selection to ensure optimal performance and durability.

What are the advantages of using plastic gears in machinery?

Plastic gears offer several advantages when used in machinery. Here’s a detailed explanation of the advantages of using plastic gears:

- Lightweight: Plastic gears are significantly lighter in weight compared to metal gears. This lightweight characteristic is particularly beneficial in applications where weight reduction is important, as it can contribute to energy efficiency, lower inertia, and reduced wear on supporting components.

- Low Noise and Vibration: Plastic gears have inherent damping properties, which help reduce noise and vibration levels during operation. The ability to absorb and dissipate vibrations leads to quieter machinery, making plastic gears suitable for applications where noise reduction is desired, such as in consumer electronics or office equipment.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals. This makes plastic gears suitable for applications in corrosive environments, where metal gears may suffer from degradation or require additional protective coatings.

- Self-Lubrication: Some plastic materials used for gear manufacturing have self-lubricating properties. These materials can reduce friction and wear between gear teeth, eliminating the need for external lubrication. Self-lubricating plastic gears can simplify maintenance requirements and reduce the risk of lubricant contamination or leakage in machinery.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production. Plastic materials are often less expensive than metals, and the manufacturing processes for plastic gears can be more efficient, resulting in lower overall production costs. This cost advantage makes plastic gears an attractive option for applications where budget considerations are important.

- Design Flexibility: Plastic gears offer greater design flexibility compared to metal gears. Plastic materials can be easily molded into complex shapes, allowing for the creation of custom gear profiles and tooth geometries. This design flexibility enables gear optimization for specific applications, improving performance, efficiency, and overall machinery design.

- Electrical Insulation: Plastic gears provide electrical insulation properties, which can be advantageous in machinery where electrical or electronic components are in close proximity to the gears. The electrical insulation helps prevent the risk of electrical short circuits or interference caused by metal gears coming into contact with conductive parts.

It’s important to note that while plastic gears offer unique advantages, they also have limitations. They may not be suitable for applications requiring extremely high torque, high temperatures, or where precise positioning is critical. The selection of plastic gears should consider the specific requirements of the machinery and the mechanical properties of the chosen plastic material.

editor by CX 2024-04-04

China Professional Steel/Brass Steering Pinion Screw Shaft Worm Gear by Hobbing Machine supplier

Product Description

Steel/Brass Steering Pinion Screw Shaft Worm Gear by Hobbing Machine

Product Description

Operating principle

A special design of the CHINAMFG is the so-called worm. In this case, the tooth winds around the worm shaft like the thread of a screw. The mating gear to the worm is the worm gear. Such a gearbox, consisting of worm and worm wheel, is generally referred to as a worm drive.

Power transmission

In worm drives, power is transmitted almost exclusively through sliding between the flanks of the worm and the worm gear, i.e. the flanks slide CHINAMFG each another as a screw. Worms are ultimately a special case of screw gears. In contrast to screw gears, which generate a point-shaped flank contact, worms have a linear flank contact. This results in the advantage of transmitting higher power at higher transmission ratios.

Due to the sliding processes and the associated friction on the flanks, the efficiency of worm drives is generally lower than wirh spur gear drives or bevel gear drives. Due to the heat generated by friction, worm drives must be cooled at high power transmissions in addition to lubrication.

1.High skilled and well-trained working team under good management environment;

2. Quick response and support for any inquiries;

3. Over 10 years professional manufacture experience to ensure high quality of your products;

4. Large and strong production capacity to meet your demand;

5. High Quality standard and hygienic environment;

6. We have very strict quality control process:

a. In coming Quality control (IQC) – All incoming raw material are checked before used.

b. In process quality control (IPQC) – Perform inspections during the manufacturing process.

c. Final quality control (FQC) – All finished goods are inspected according to our quality

standard for each products.

d. Outgoing Quality Control (OQC) – Our QC team will 100% full inspection before it goes

out for shipment.

7. Good after sales services;

Material Available:

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Advantages | »Reliable CNC service »Good machining quality »Reasonable Pricing provided »Competitive shipping cost service »MOQ 1PCS and small quantity order accepted »Professional engineering service when any modification required »Any turnkey assembly or customized package requirements, we’ll meet your demands! |

| RFQ | Customer Inquiry →Engineering Communication →Cost Analysis →Sales Analysis →Quote to Customer » 1-3 Work Days Only » Submit RFQ with complete commercial terms |

| Sample Making | Sample Order → Engineering Review → Sample Plan to Customer → Sample Status Tracking → Submit Samples with Doc. » Tooling L/T: 2-4 weeks, Sample L/T: 1 week » Continuous Sample Status Tracking » Complete Documents for sample approval |

| Order Management | CRM System → Open Order Confirm → Logistic Arrangement. » Production L/T: 2-4 wks » Weekly Open Order Confirm » Preferred 3PL Service to Customers |

| Quality Control | Certificates: RoHS, ISO9001:2008, SGS. IQC → IPQC → OQC/FQC → Quality Complain Feedback → Audit & Training. » Plant Audit and Qualified by world famous company » Strict Quality Management Procedure with Traceability |

| Application | »Aerospace »Marine »Motorbike »Automotive »PhotoGear »EDC Tools » lighting fittings »Office equipment »Home appliance »Medical equipment »Telecommunication »Electrical & Electronics »Fire detection system, etc. |

Inspections:

3D instruments, 2D instruments, Projectors, Height Gauges, Inner diameter dial indicators, Dial gaues,

Thread and Pin gauges, Digital calipers,Micro calipers, Thickness testers, Hardness testers Roughness

testers, etc.( Detection accuracy to 0.001 millimetre )

Q: Why choose CHINAMFG product?

A: We CHINAMFG have our own plant– HangZhou CHINAMFG machinery Co.,Ltd, therefore, we can surely

promise the quality of every product and provide you comparable price.

Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

Q: Do you provide customized precision machining parts?

A: Yes. Customers give us drawings and specifications, and we will manufact accordingly.

Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

Quality First,Price Best,Service Foremost!

We assure you of our best services at all times !

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample stamping parts

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the lifespan of a typical worm gear?

The lifespan of a typical worm gear can vary depending on several factors, including the quality of materials, design, operating conditions, maintenance practices, and the specific application. Here’s a detailed explanation of the factors that influence the lifespan of a worm gear:

1. Quality of materials: The choice of materials used in the construction of the worm gear greatly impacts its lifespan. High-quality materials, such as hardened steel or bronze, offer better durability, wear resistance, and overall longevity compared to lower-quality materials. The selection of appropriate materials based on the application requirements is crucial for achieving a longer lifespan.

2. Design considerations: The design of the worm gear, including factors such as tooth profile, size, and load distribution, can influence its lifespan. Well-designed worm gears with optimized tooth geometry and proper load-carrying capacity tend to have longer lifespans. Additionally, features like lubrication systems and anti-backlash mechanisms can also contribute to improved durability and extended lifespan.

3. Operating conditions: The operating conditions under which the worm gear operates play a significant role in determining its lifespan. Factors such as load magnitude, speed, temperature, and environmental conditions can affect the wear and fatigue characteristics of the gear. Properly matching the worm gear to the application requirements and ensuring that it operates within specified limits can help prolong its lifespan.

4. Maintenance practices: Regular maintenance and proper lubrication are essential for maximizing the lifespan of a worm gear. Adequate lubrication helps reduce friction, wear, and heat generation, thereby extending the gear’s life. Regular inspections, lubricant replenishment, and timely replacement of worn or damaged components are important maintenance practices that can positively impact the lifespan of the worm gear.

5. Application-specific factors: The specific application in which the worm gear is used can also influence its lifespan. Factors such as operating cycles, torque levels, shock loads, and duty cycles vary between applications and can impact the wear and fatigue experienced by the gear. Understanding the unique requirements and demands of the application and selecting a worm gear that is appropriately rated and designed for those conditions can contribute to a longer lifespan.

Given the variations in materials, designs, operating conditions, and maintenance practices, it is challenging to provide a specific lifespan for a typical worm gear. However, with proper selection, installation, and maintenance, worm gears can have a lifespan ranging from several years to decades, depending on the factors mentioned above.

It is worth noting that monitoring the performance of the worm gear through regular inspections and addressing any signs of wear, damage, or excessive backlash can help identify potential issues early and extend the gear’s lifespan. Additionally, following the manufacturer’s guidelines and recommendations regarding maintenance intervals, lubrication types, and operating limits can significantly contribute to maximizing the lifespan of a worm gear.

Can worm gears be used in heavy-duty machinery and equipment?

Yes, worm gears can be used in heavy-duty machinery and equipment. Here’s a detailed explanation of their suitability for such applications:

1. High torque transmission: One of the key advantages of worm gears is their ability to transmit high torque. The unique design of the worm and worm wheel allows for efficient torque generation and power transmission. This makes worm gears well-suited for heavy-duty applications that require the transfer of substantial rotational forces.

2. Compact size: Worm gears offer a compact and space-saving solution for heavy-duty machinery. Their compact design allows for the transmission of high torque in a relatively small package. This is particularly advantageous in applications where space constraints or compact design requirements are present.

3. Self-locking feature: Worm gears exhibit a self-locking characteristic, meaning that the worm can prevent the back-driving of the gear system. This feature is beneficial in heavy-duty machinery where it is essential to maintain a fixed position or prevent the system from reversing under load. The self-locking capability of worm gears provides stability and safety in various heavy-duty applications.

4. High gear ratios: Worm gears can achieve high gear ratios, which is advantageous in heavy-duty machinery that requires precise speed reduction. The high gear ratios allow for fine control of rotational speed and torque output, enabling the gear system to match the requirements of heavy loads and demanding operating conditions.

5. Durable construction: Worm gears are typically manufactured using robust materials such as alloy steels, cast iron, or bronze. These materials offer excellent strength, wear resistance, and durability, making worm gears capable of withstanding the heavy loads and harsh operating environments encountered in heavy-duty machinery.

6. Overload protection: The unique design of worm gears provides inherent overload protection. When the load exceeds the gear’s capacity, the sliding action between the worm and worm wheel causes a high frictional force, limiting the torque transmission and preventing damage to the gear system. This overload protection feature is valuable in heavy-duty machinery where sudden load spikes or unexpected overloads can occur.

7. Wide range of applications: Worm gears find applications in various heavy-duty machinery and equipment across different industries. Some examples include cranes, winches, elevators, mining machinery, construction equipment, rolling mills, heavy-duty conveyors, and marine propulsion systems. The versatility of worm gears makes them suitable for a wide range of heavy-duty applications.

It is important to note that while worm gears offer several advantages for heavy-duty machinery, there are certain considerations to keep in mind. These include proper lubrication to minimize friction and wear, adequate cooling to manage heat generation, proper alignment to ensure efficient power transmission, and regular maintenance to inspect for signs of wear or damage. By addressing these factors, worm gears can reliably and effectively meet the demands of heavy-duty machinery and equipment.

How does a worm gear differ from other types of gears?

A worm gear differs from other types of gears in several ways. Here are the key differences:

- Gear Configuration: A worm gear consists of a threaded worm and a mating gear, known as the worm wheel or worm gear. The worm has a helical thread that meshes with the teeth of the worm wheel. In contrast, other types of gears, such as spur gears, bevel gears, and helical gears, have parallel or intersecting axes of rotation.

- Gear Ratio: Worm gears provide high gear reduction ratios compared to other types of gears. The ratio is determined by the number of teeth on the worm wheel and the number of threads on the worm. This high reduction ratio allows worm gears to transmit more torque while maintaining a compact size.

- Direction of Rotation: In a worm gear system, the worm can drive the worm wheel, but the reverse is not true. This is due to the self-locking nature of worm gears. The angle of the worm’s helical thread creates a wedging action that prevents the worm wheel from backdriving the worm. This characteristic makes worm gears suitable for applications requiring a mechanical brake or holding position.

- Efficiency: Worm gears typically have lower efficiency compared to other types of gears. This is primarily due to the sliding action between the worm’s threads and the worm wheel’s teeth, which leads to higher friction and energy losses. Therefore, worm gears are not ideal for applications that require high efficiency or continuous, high-speed operation.

- Lubrication: Worm gears require proper lubrication to reduce friction and wear. The sliding action between the worm and the worm wheel generates heat, which can affect the performance and lifespan of the gear system. Lubricants help to dissipate heat and provide a protective film between the mating surfaces, reducing friction and extending the gear’s life.

- Applications: Worm gears are commonly used in applications that require high gear reduction, compact size, and self-locking capabilities. They are found in various industries, including elevators, automotive steering systems, machine tools, robotics, and winding mechanisms.

Overall, the unique design and characteristics of worm gears make them suitable for specific applications where high torque, compactness, and self-locking features are essential, even though they may have lower efficiency compared to other types of gears.

editor by CX 2024-04-04

China wholesaler OEM ODM Customized Nylon Transmission Internal Spur Plastic Gear for 3c Industry Equipment straight bevel gear

Product Description

OEM ODM Customized Nylon Transmission Internal Spur Plastic Gear for 3c Industry Equipment

Gear transmission relies on the thrust between gear teeth to transmit motion and power, also known as meshing transmission. With this gradual meshing, helical gears operate much more smoothly and quietly than spur gears. Therefore, almost all automobile transmissions use helical gears.Since the teeth on the helical gear present a certain angle, the gears will be under a certain amount of stress when they mesh. Equipment using helical gears is equipped with bearings to withstand this pressure.

Product Parameters

| Product name | Spur Gear & Helical Gear & Gear Shaft |

| Customized service | OEM, drawings or samples customize |

| Materials Available | Stainless Steel, Carbon Steel, S45C, SCM415, 20CrMoTi, 40Cr, Brass, SUS303/304, Bronze, Iron, Aluminum Alloy etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Surface Treatment | Conditioning, Carburizing and Quenching,Tempering ,High frequency quenching, Tempering, Blackening, QPQ, Cr-plating, Zn-plating, Ni-plating, Electroplate, Passivation, Picking, Plolishing, Lon-plating, Chemical vapor deposition(CVD), Physical vapour deposition(PVD)… |

| BORE | Finished bore, Pilot Bore, Special request |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Pressure Angle | 20 Degree |

| Hardness | 55- 60HRC |

| Size | Customer Drawings & ISO standard |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001:2008 |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Printing Equipment Industry, Laser Equipment Industry, Automated Assemblyline Industry, Woodening Industry, Packaging Equipment Industry, Logistics storage Machinery Industry, Robot Industry, Machine Tool Equipment Industry |

Company Profile

FAQ

| Main markets | North America, South America,Eastern Europe,Weat Europe,North Europe.South Europe,Asia |

| How to order | *You send us drawing or sample |

| *We carry through project assessment | |

| *We give you our design for your confirmation | |

| *We make the sample and send it to you after you confirmed our design | |

| *You confirm the sample then place an order and pay us 30% deposit | |

| *We start producing | |

| *When the goods is done,you pay us the balance after you confirmed pictures or tracking numbers | |

| *Trade is done,thank you! |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Automation Equipment |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Plastic |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you choose the right type of plastic material for specific applications?

Choosing the right type of plastic material for specific applications requires careful consideration of various factors. Here’s a detailed explanation of the process:

1. Identify Application Requirements: Begin by understanding the specific requirements of the application. Consider factors such as temperature range, chemical exposure, mechanical stress, electrical properties, dimensional stability, and regulatory compliance. This initial assessment will help narrow down the suitable plastic material options.

2. Research Plastic Material Properties: Conduct thorough research on different types of plastic materials and their properties. Consider factors such as mechanical strength, thermal stability, chemical resistance, electrical conductivity, impact resistance, UV stability, and food safety approvals. Plastic material datasheets and technical resources from manufacturers can provide valuable information.

3. Evaluate Material Compatibility: Assess the compatibility of the plastic material with the surrounding environment and other components in the system. Consider the potential for chemical reactions, galvanic corrosion, thermal expansion, and any specific requirements for mating surfaces or interfaces. Ensure the selected material is compatible with the intended operating conditions.

4. Consider Manufacturing Process: Evaluate the manufacturing process involved in producing the desired component or product. Different plastic materials may have specific requirements or limitations for processes such as injection molding, extrusion, blow molding, or machining. Ensure the chosen material is compatible with the selected manufacturing method and can meet the desired quality and production efficiency.

5. Assess Cost and Availability: Consider the cost and availability of the plastic material. Some specialty or high-performance plastics may be more expensive or have limited availability compared to more common materials. Evaluate the cost-effectiveness and feasibility of using the selected material within the project’s budget and timeline.

6. Consult with Material Experts: If necessary, consult with material experts, engineers, or suppliers who have expertise in plastic materials. They can provide valuable insights and recommendations based on their experience and knowledge of specific applications. Their input can help ensure the optimal material selection for the intended use.

7. Perform Prototype and Testing: Before finalizing the material selection, it’s advisable to produce prototypes or conduct testing using the chosen plastic material. This allows for verification of the material’s performance, dimensional accuracy, strength, durability, and other critical factors. Iterative testing and evaluation can help refine the material selection process if needed.

By following these steps and considering the application requirements, material properties, compatibility, manufacturing process, cost, and expert advice, it’s possible to choose the most appropriate plastic material for specific applications. Proper material selection is crucial for ensuring optimal performance, longevity, and safety in various industries and products.

How do plastic gears handle lubrication and wear?

Plastic gears handle lubrication and wear differently compared to metal gears. Here’s a detailed explanation of their behavior:

1. Lubrication in Plastic Gears: Lubrication plays a crucial role in the performance and longevity of plastic gears. While metal gears often require continuous lubrication, plastic gears have different lubrication requirements due to their inherent properties. Here are some key considerations:

- Self-Lubrication: Some plastic materials, such as certain formulations of polyoxymethylene (POM), have inherent self-lubricating properties. These materials have a low coefficient of friction and can operate with minimal lubrication or even dry. Self-lubricating plastic gears can be advantageous in applications where the use of external lubricants is impractical or undesirable.

- Lubricant Compatibility: When external lubrication is necessary, it’s important to choose lubricants that are compatible with the specific plastic material used in the gears. Certain lubricants may degrade or adversely affect the mechanical properties of certain plastics. Consultation with lubricant manufacturers or experts can help identify suitable lubricants that won’t cause degradation or wear issues.

- Reduced Lubricant Requirements: Plastic gears generally have lower friction coefficients compared to metal gears. This reduced friction results in lower heat generation and less wear, which in turn reduces the demand for lubrication. Plastic gears may require less frequent lubricant replenishment or lower lubricant volumes, reducing maintenance requirements.

- Appropriate Lubricant Application: When applying lubricant to plastic gears, care should be taken to avoid excessive amounts that could lead to contamination or leakage. Lubricants should be applied in a controlled manner, ensuring they reach the critical contact points without excessive buildup or excess spreading beyond the gear surfaces.

2. Wear in Plastic Gears: Plastic gears exhibit different wear characteristics compared to metal gears. While metal gears typically experience gradual wear due to surface interactions, plastic gears may undergo different types of wear mechanisms, including:

- Adhesive Wear: Adhesive wear can occur in plastic gears when high loads or speeds cause localized melting or deformation at the gear teeth contact points. This can result in material transfer between gear surfaces and increased wear. Proper material selection, gear design optimization, and lubrication can help minimize adhesive wear in plastic gears.