Product Description

Product Description

|

Item |

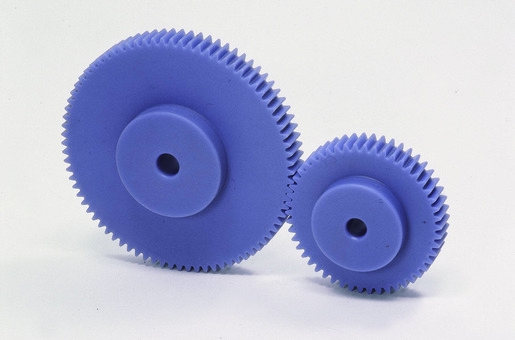

Customized OEM/ODM plastic nylon spiral bevel gears nylon bevel gears |

|

Material |

ABS, PC/ABS, PP, PC, POM(Delrin), Nylon 6, Nylon 6/6, PA 12, HDPE, LDPE, PS(HIPS), SAN/AS, ASA, PVC, UPVC, TPE, TPR, PU, TPU, PET, PEI(Ultem), PSU, PPSU, PPE/PS, PTFE, GPPS, PPO, PES, CA, etc |

|

Certificate |

IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/F D A |

|

Drawing Format |

.stp / .step / .igs /.CHINAMFG /.dwg / .pdf |

|

Color |

Almost all PMS colors available. |

|

Parameters |

Inch, centimeter, millimeter, etc. |

|

Function |

Industrial parts /daily supply / Medical grade supply, etc. |

|

Surface Treatment |

Matte, Common polishing, Mirror polishing, Texture, Plating, Power Coating (Painting), Laser Engraving, Brushing, Marbling, Printing etc. |

|

Mold Material |

S136H, 718H, NAK80, P20, H13, etc. |

|

Mold Precision |

If no special request, apply to SJ/T10628-1995 standards, class 3. |

|

Mold Life-cycle |

100,000-500,000 shots. |

|

Packing |

Pack in bulk / poly bag / bubble bag / color box. |

|

Sample |

Available. One cavity sample mold or 3D printing. |

|

Price Tip |

The price shown above is just for reference, final actual price depends on your design, material request, surface treatment, order qty, package request, etc. |

Customized OEM/ODM plastic nylon spiral bevel gears nylon bevel gears

1. Rapid Prototyping & On-demand production services;

2. Professional DFM Report before Mould Making;

3.Capability for Plastic Injection Molding is up to 1500mm

DFM Report (Design for Manufacturability) for Reference.

Some Custom CHINAMFG & Moulds for Your Reference.

Neway Highly Welcome Your Own Custom Designs !!!

Neway Support Custom Design Moulds & Moulds Export.

Neway Can Also Provide Mould Spare Parts Export, eg: Slider, Inserts, Ejector Pins, etc.

NEWAY has complete production chain from R&D, Rapid Prototypes, mould design, mould making, components production, assembling, packing to export. Having 1 supplier like CHINAMFG for the complete assembly will allow for better design, quality, and fit of all the individual parts.

The most common used surface treatment are: Matte, Texture (fine texture, rough texture…), Common Polishing, Mirror Polishing, Laser Engraving, Printing, Plating, Brushing, Marbling), etc. You can view below surface pictures for reference

Company Profile

Our Advantages

Good reviews of customer

Certifications

Below are some inspection equipment for reference:

And attach the injection molding CHINAMFG inspection report for reference:

Packaging & Shipping

FAQ

Q1. How soon can I get a precise quotation for custom plastic injection part?

A1: Please send us your inquiry by email or Alibaba TM message. Once we confirm the design (Feature details with parameters), material, color, qty, we can provide quotation within 24 HOURS.

Q2: Can I get a free sample, how long will it take?

A2: a. For standard products we have in stock, YES for free sample, but the express fee will be charged in advance.

Mostly, it takes 3-10 days.

b. For custom products, sample fee is determined by the detailed sample requirements. Normally, it takes 7-15 days.

Q3: Can you make custom parts based on my sample?

A3: Yes, you can send the sample to us by express and we will evaluate the sample, scan the features and draft 3D drawing for production.

Q4: What does your OEM service include?

A4: We follow up your request from the design idea to the mass production.

a. You can provide 3D drawing to us, then our engineers and production teams evaluate the design and quote you the precise cost.

b. If you don’t have 3D drawing, you can provide 2D drawing or draft with features details with full dimensions, we can draft 3D drawing for you with fair charge.

c. You can also customize Logo on the product surface, package, color box or carton.

d. We also provide assembly service for the OEM parts.

Q5. What is your payment term?

A5: We accept T/T, Paypal, Western Union, L/C, Alibaba Trade Assurance.

Work with Neway, your business is in safe and your money is in safe!

If you can dream it, we can build it!

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Car, Others |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Plastic Injection |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | Plastic |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

What is the impact of temperature variations on plastic gears?

Temperature variations can have a significant impact on plastic gears. Here’s a detailed explanation of their effects:

1. Thermal Expansion: Plastic gears can experience thermal expansion or contraction with changes in temperature. Different types of plastics have varying coefficients of thermal expansion, meaning they expand or contract at different rates. This can result in dimensional changes, which may affect the gear’s meshing, clearance, and overall performance. It’s important to consider the thermal expansion characteristics of the specific plastic material used in the gear design.

2. Material Softening or Hardening: Plastic materials can exhibit changes in mechanical properties with temperature variations. In general, as temperature increases, plastic materials tend to soften and become more flexible, while at lower temperatures, they can become stiffer and more brittle. These changes can impact the gear’s load-bearing capacity, wear resistance, and overall durability. It’s crucial to select plastic materials that can maintain their mechanical integrity within the expected temperature range of the application.

3. Dimensional Stability: Plastic gears may experience dimensional changes or warping due to temperature fluctuations. Higher temperatures can cause plastic materials to deform, leading to misalignment, increased backlash, or reduced gear accuracy. Conversely, lower temperatures can cause contraction, resulting in tight clearances, increased friction, or gear binding. Proper design considerations, including material selection and gear geometry, can help mitigate the impact of temperature-induced dimensional changes.

4. Lubrication and Wear: Temperature variations can affect the lubrication properties of plastic gears. Higher temperatures can cause lubricants to degrade or become less effective, leading to increased friction, wear, and potential gear failure. Similarly, low temperatures can cause lubricants to thicken or solidify, hindering proper lubrication and increasing wear. Selecting lubricants suitable for the anticipated temperature range and periodic maintenance can help ensure proper lubrication and minimize wear on plastic gears.

5. Cold Flow and Creep: Some plastic materials, especially those with lower glass transition temperatures, may exhibit cold flow or creep at elevated temperatures. Cold flow refers to the gradual deformation or flow of plastic material under constant stress, while creep refers to the time-dependent deformation under a constant load. These phenomena can cause changes in gear geometry, tooth profile, or tooth engagement over time, potentially affecting gear performance and functionality. Understanding the material’s creep and cold flow characteristics is important when selecting plastic gears for applications exposed to temperature variations.

6. Impact on Lubricants and Seals: Temperature variations can also impact the performance of lubricants and seals used in gear systems. Extreme temperatures can cause lubricants to break down, lose viscosity, or leak from the gear assembly. Seals and gaskets may also be affected, leading to compromised gear housing integrity or increased friction. It’s crucial to consider temperature compatibility and select appropriate lubricants and seals that can withstand the anticipated temperature range.

In summary, temperature variations can significantly impact plastic gears by causing thermal expansion, material softening or hardening, dimensional changes, lubrication issues, cold flow or creep, and effects on lubricants and seals. Proper material selection, design considerations, and understanding the anticipated temperature range are essential to ensure the reliable and optimal performance of plastic gears in various applications.

What are plastic gears and how are they used?

Plastic gears are gear components made from various types of polymers or plastic materials. They offer unique properties and advantages compared to traditional metal gears. Here’s a detailed explanation of plastic gears and their applications:

- Types of Plastic Materials: Plastic gears can be manufactured from different types of polymers, including thermoplastics such as acetal (polyoxymethylene – POM), nylon (polyamide – PA), polycarbonate (PC), and polyethylene (PE), as well as thermosetting plastics like phenolic resins. Each material has its own specific characteristics, such as strength, wear resistance, and temperature resistance, which make them suitable for different applications.

- Advantages of Plastic Gears: Plastic gears offer several advantages over metal gears, including:

- Lightweight: Plastic gears are lighter in weight compared to metal gears, which can be beneficial in applications where weight reduction is important.

- Low Noise and Vibration: Plastic gears can provide quieter operation due to their inherent damping properties that reduce noise and vibration levels.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals, making them suitable for applications in corrosive environments.

- Self-Lubrication: Some plastic materials have self-lubricating properties, reducing the need for external lubrication and simplifying maintenance.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production, due to the lower material and manufacturing costs.

- Applications of Plastic Gears: Plastic gears find applications in various industries and systems, including:

- Automotive: Plastic gears are used in automotive systems such as windshield wipers, HVAC systems, seat adjusters, and electric power steering systems.

- Consumer Electronics: Plastic gears are commonly found in consumer electronics like printers, scanners, cameras, and home appliances.

- Medical Devices: Plastic gears are used in medical equipment and devices where weight reduction, low noise, and corrosion resistance are desired.

- Toy Manufacturing: Plastic gears are extensively used in the production of toys, including mechanical toys, hobby models, and educational kits.

- Office Equipment: Plastic gears are employed in office equipment like printers, copiers, and scanners, where quiet operation and cost-effectiveness are important.

- Industrial Machinery: Plastic gears can be utilized in various industrial machinery applications, such as conveyor systems, packaging equipment, and textile machinery.

It’s important to note that while plastic gears offer unique advantages, they also have limitations. They may not be suitable for applications requiring extremely high torque, high temperatures, or where precise positioning is critical. The selection of plastic gears should consider the specific requirements of the application and the mechanical properties of the chosen plastic material.

editor by CX 2023-11-03